Who We Are

Founded in 2008, Spiroplast Factory LLC has grown into a state-of-the-art manufacturing facility, adhering to national standards of Ukraine, EU regulations, and international quality requirements. Our products have earned a stellar reputation across numerous countries.

What Sets Us Apart

At Spiroplast, we specialize in producing unique and innovative solutions, including dual-layer SPIRO pipes and Protect Crack Resist technology, along with polypropylene pipes. These advanced products enable the construction of modern water supply and drainage systems.

Our facilities produce polymer pipes for water, sewage, gas, and heating systems, with diameters ranging from 20 mm to 3000 mm. We also manufacture wells for outdoor sewage systems up to 2200 mm in diameter, as well as tanks of various configurations for diverse applications.

Our Production Lines

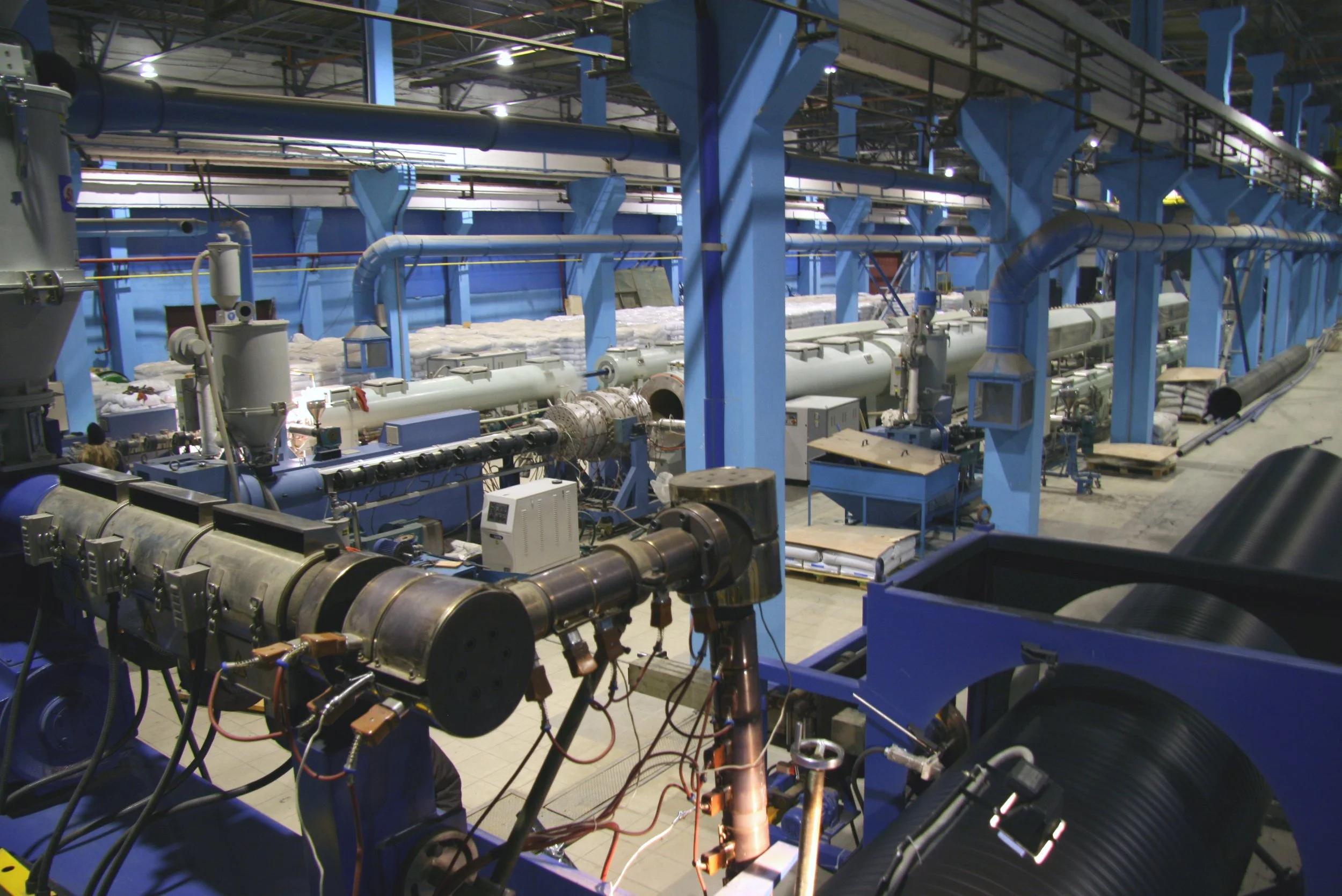

Pressure Pipe Production Line

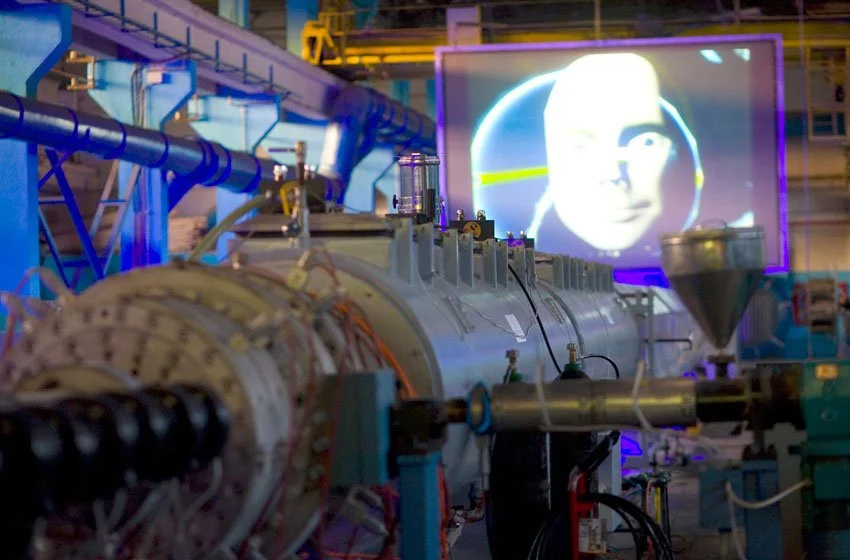

SPIRO Pipe Production Line

Equipped with cutting-edge extrusion machinery and automated monitoring systems, our factory is staffed by highly skilled specialists to ensure top-quality production. We manufacture pipes using PE-100 polyethylene and PP-80 polypropylene, renowned for their durability and reliability.

Quality Assurance Laboratory

The Spiroplast Quality Control Laboratory is unparalleled in its capabilities. It conducts rigorous incoming inspections of polyethylene raw materials and acceptance tests for finished products, following technical and regulatory documentation.

Key Quality Tests:

Strength and thermal stability

Ring stiffness

Resistance to slow crack propagation

Our laboratory is accredited by the Ukrainian State Committee on Technical Regulation and Consumer Policy.

In 2007, we developed technical specifications TU U 25.2-31149692-001:2007 for polyethylene pipes (PE-63, PE-80, PE-100). In 2009, Spiroplast LLC earned ISO 9001-2001 certification for quality management systems, further solidifying our commitment to excellence.

Spiroplast Factory LLC: Setting the Standard for Modern Infrastructure.